AI-Driven Inspections for Buildings, Bridges, and Critical Infrastructure

We deliver fast, accurate, and data-driven structural assessments using drones, LiDAR, and advanced AI damage detection down to 0.1 mm.

What's wrong with Traditional Infrastructure Safety Inspections?

SafetyRisks: Inspectors work at hazardous heights, over water, or near traffic, using scaffolding, cranes, or special vehicles, increasing accident risk.

High Cost & Resources: Manual inspections need large crews, specialized vehicles, and long setups; indirect costs from traffic disruptions are high.

Inefficiency: Inspections take days or weeks for large bridges, limiting inspection capacity.

Subjectivity & Errors: Results depend on inspector judgment; defects may be missed or inconsistently recorded.

Limited Data: Manual inspections rely on visual checks and notes, lacking consistent digital data and precise quantitative analysis.

Public Disruption: Traffic closures cause congestion and economic loss in busy areas.

Unsustainable: Aging infrastructure and inspection demand require faster, automated, data-driven solutions beyond manual methods.

Our Solution

Drone + AI-powered inspections with KO-DETECT PRO

Safer for workers | Faster turnaround | Cost-effective | Data-driven accuracy

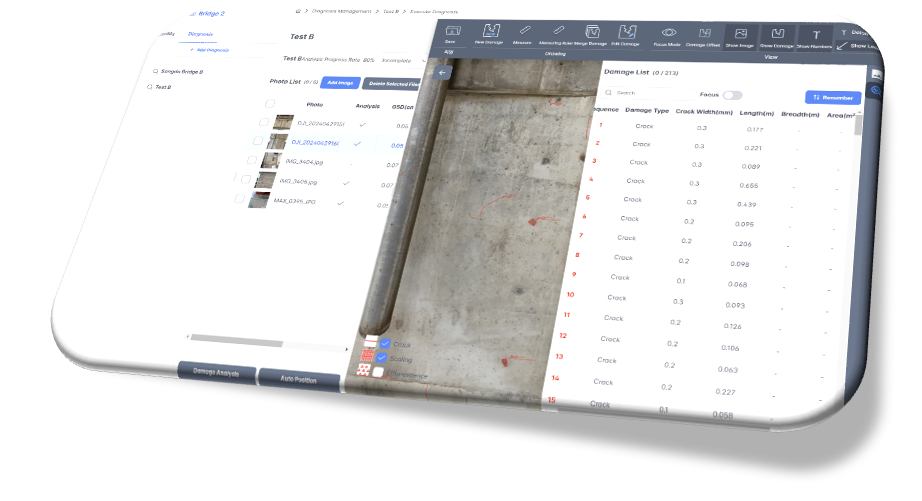

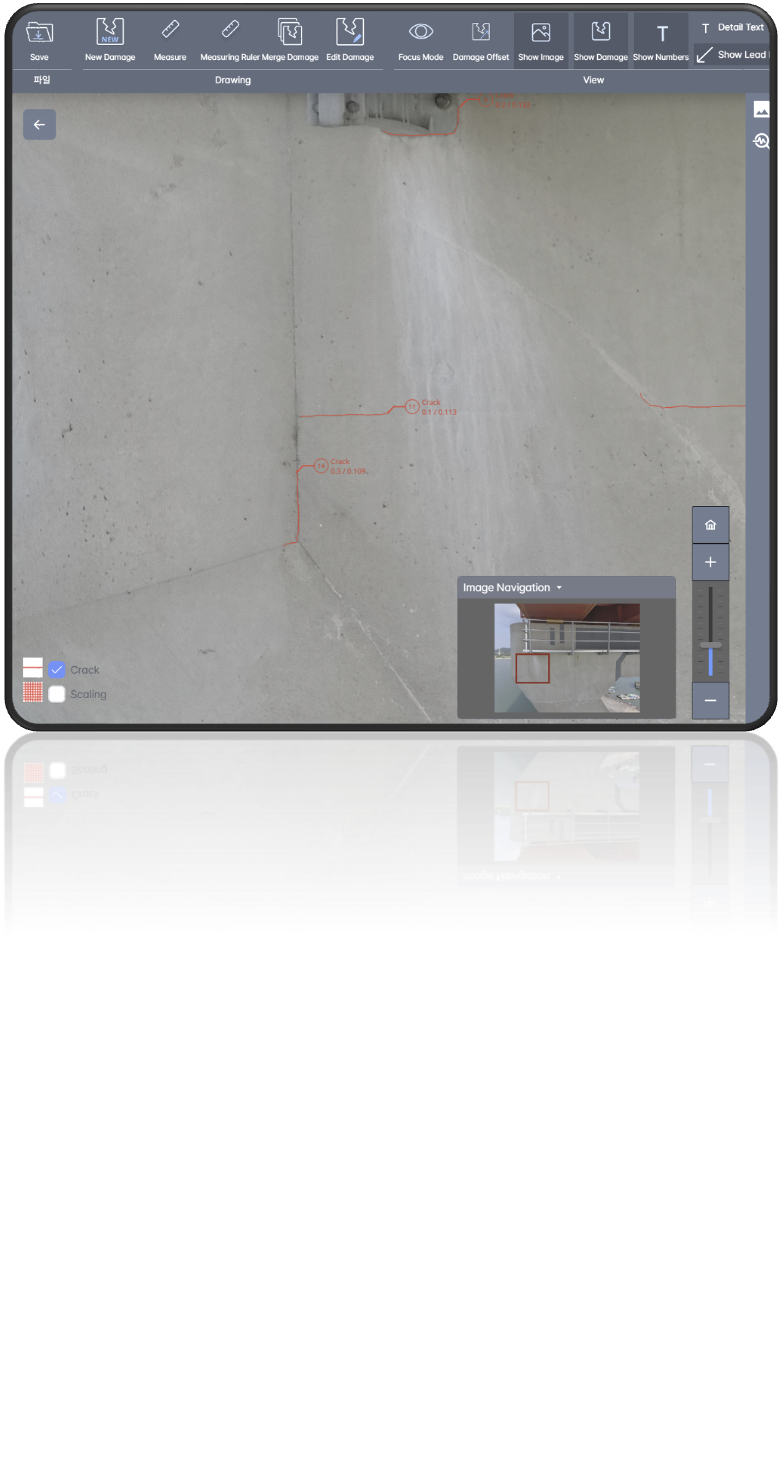

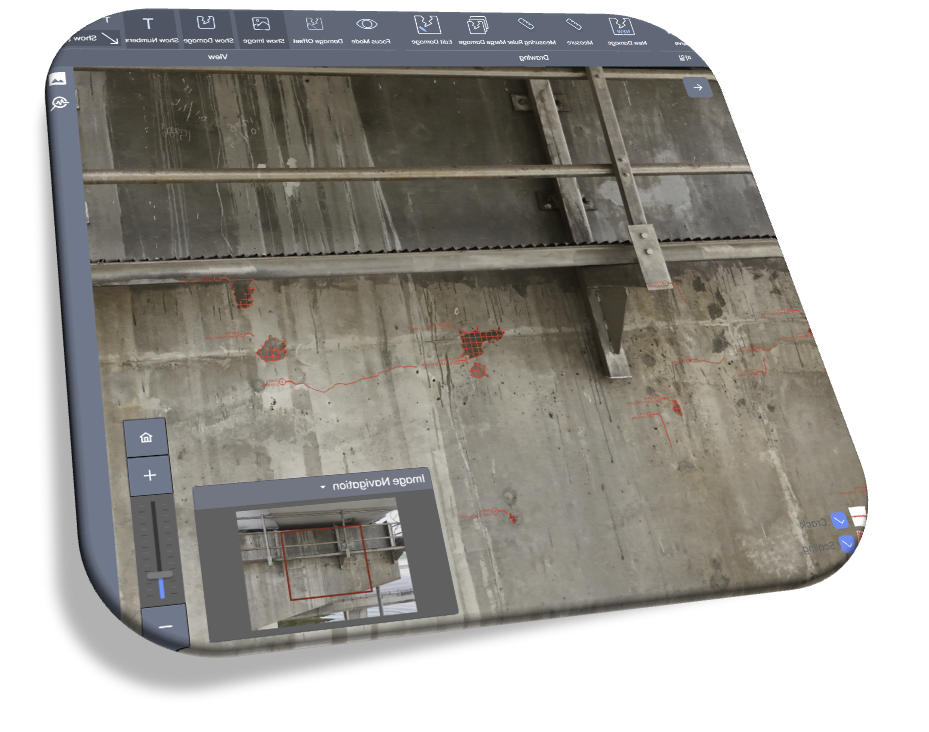

KO-DETECT PRO AI-Powered Damage Detection Solution

98% Faster Inspections – Capture and analyze data within minutes.

0.1 mm Accuracy – Detect micro-cracks invisible to manual inspection.

Orthomosaics – High-fidelity reporting and visualization.

Safe & Non-Intrusive – No scaffolding, lifts, lane closures, or risk to personnel.

How It Works

Fly – Capture high-resolution images with drones.

Analyze – AI detects cracks, spalling, corrosion, delamination, and more.

Report – Export actionable insights + inspection history.

Monitor – Track damage progression over time.

Advantages of AI-Digital Safety and Damage Inspections

-

Ensuring worker safety through remote inspection text goes here

-

Identify cracks, spalling, corrosion, and other defects using pixel-level AI analysis.

-

Data-based quantification of damage volumes

-

Track crack progression and structural behavior over time with time-series analysis.

Inspection Period

-50%

Reduced Inspection Time

Safety

-96%

Reduced Risk Exposure By

Inspection Cost

-40%

Reduced Inspection Cost By

Detection Rate

-96%

Damage Detection Accuracy Over

KO-DETECT PRO: Faster, more accurate, unbiased digital data.

KO-DETECT PRO: Faster, more accurate, unbiased digital data.

Industries Served

Transportation

Railways, bridges, tunnels, metro lines

Commercial Buildings

Hotels, office towers, malls, apartments.

Government & Municipalities

Public infrastructure, schools, hospitals.

Construction & Engineering

QC verification, progress documentation, as-built surveys.